Tecno Med B

Friction Bar, specialisation course for friction elements on zirconia bars

|

|

Target group: | Zirkonzahn zirconia and system users | |

|

|

Course duration: | 3 days | |

|

|

Participants: | 4 | |

|

|

Venue: | Zirkonzahn Education Center Brunico, Education Center Neuler other venues on request | |

|

|

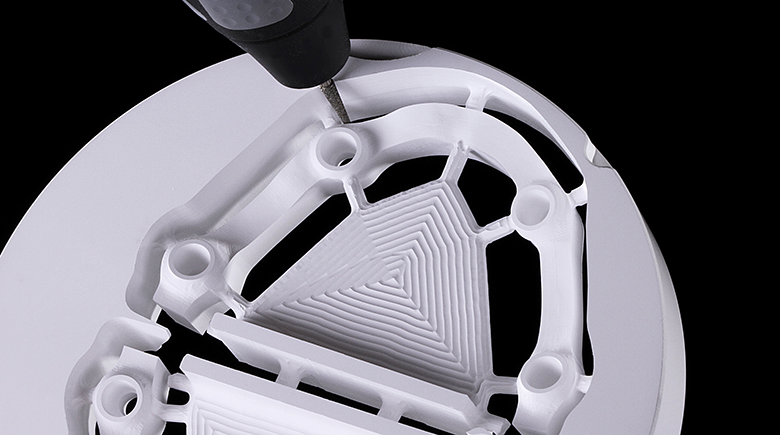

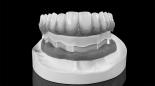

Content: | We prepare a model with a pre-sintered zirconia bar for you and instruct you in elaborating the friction element made of Tecno Med resin. We will show you how to fix the zirconia bar on the titanium bases, parallelise it, store it in the software and how to subsequently model and mill the friction coping as well as the tertiary structure. Finally, we bond the friction coping to the resin superstructure veneered with Gingiva-Composites and let it slide with friction on the zirconia bar. |

Programme

Day 1 (all-day)

- Cemention of the titanium bases in the densely sintered zirconia bar

- Parallelisation, polishing and finalisation of the zirconia bar

- Software and hardware of the Zirkonzahn CAD/CAM system: Zirkonzahn.Archiv, scan process, modellation of the friction element, information about the parameters for friction elements

- Test milling of the friction element

- Explanation of the CAD/CAM Bars software module

- Milling of the friction elements made of Tecno Med

Day 2 (all-day)

- Check of the milling result

- Scanning of the milled friction element

- Software and hardware of the Zirkonzahn CAD/CAM system: Setting of the parameters and carrying out a virtual wax-up

- Information about the Zirkonzahn.Nesting software and nesting of the secondary structure in a CAD/CAM resin blank

- Start of the milling process

- Visit of the Zirkonzahn headquarters in Gais

Day 3 (all-day)

- Check of the milling result

- Elaboration and polishing of the secondary structure

- Gingiva layering with Gingiva-Composites

- Finalisation of the work

- Bonding of the secondary structure with the friction element

- Final polishing of the secondary structure and review of the finished jobs

- Resolve outstanding issues