ScanAnalogs

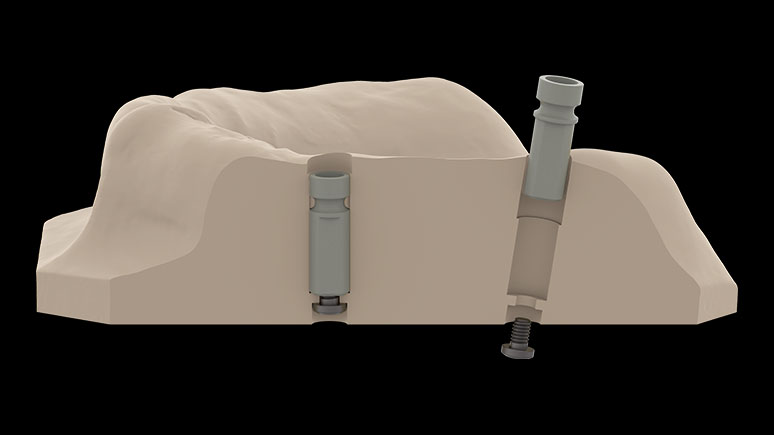

The ScanAnalogs unite the function of a laboratory analogue with the one of a scanmarker. In contrast to the conventional scanmarker, however, the ScanAnalogs are scanned directly on the impression, not the model. The ScanAnalogs are screwed onto the traditional impression copings in the impression and digitised with the Zirkonzahn scanner. The captured implant position can be directly transferred into the software without a plaster model. Physical models can then be produced from the acquired data (CAD/CAM Model Maker software module). In their role as laboratory analogue they replicate the exact position and orientation of the implants on the model.

Scananalogs are available for the following systems

*the range is continually being expanded