Raw-Abutment®

Raw-Abutment®

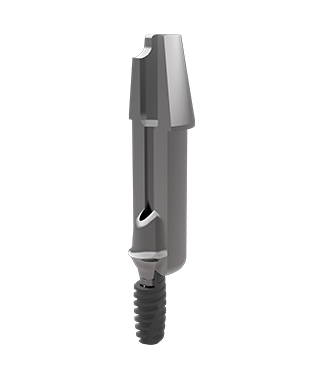

The abutment geometry is freely and individually customisable. Depending on the implant system, different Raw‑Abutment® blanks are required.

|

||

|

For single crowns | |

|

With anti-rotation device | |

|

Available with 10 mm and 14 mm diameter | |

|

Can be anodised in different colours with the Titanium Spectral-Colouring Anodizer |

- Precast abutment blanks for the manufacturing of individual abutments from a high-quality medical titanium alloy (Ti-6Al-4V ELI according to ASTM F136 and DIN EN ISO 5832-3)

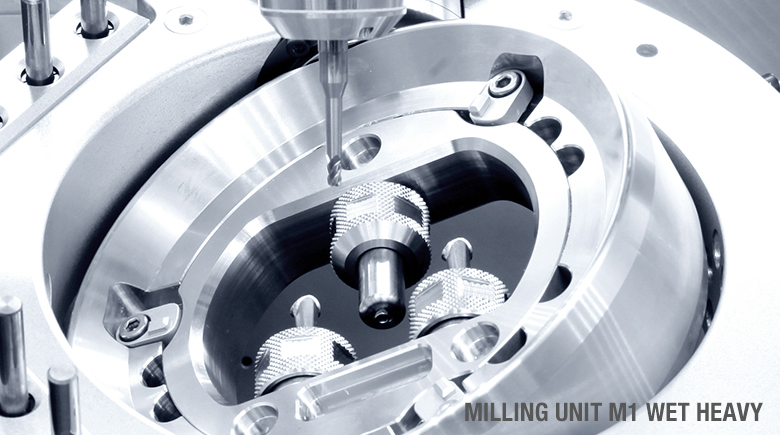

- Can be processed with the Milling Unit M1 Abutment as well as with the Milling Units M1 Wet Heavy Metal, M2 Wet Heavy Metal, M2 Dual Wet Heavy Metal, M4 Wet Heavy Metal, M5 and M5 Heavy in combination with Milling Spindle Hard Automatic, wet processing function Wet Grinding/Wet Milling and Raw-Abutment® Holder

- Fast manufacturing (20 minutes per abutment with the Milling Unit M1 Abutment, 25-30 minutes with the Milling Units M1 Wet Heavy Metal, M2 Wet Heavy Metal, M2 Dual Wet Heavy Metal, M4 Wet Heavy Metal, M5 and M5 Heavy)

- Perfect fit due to industrially precast implant connections

- Can be anodized in different colours (e.g. gold-coloured) with the Titanium Spectral-Colouring Anodizer

- Availability depending on the implant system – the range is continuously being expanded

|

|

Raw-Abutment® with highly precise and industrially precast implant connections for different implant systems |

The industrially prefabricated implant connection of the Raw-Abutment® titanium abutment blanks guarantees highest precision and fitting accuracy. The special milling strategies and milling bodies ensure a particularly smooth surface structure. Depending on the implant system, different Raw-Abutment® blanks are required. Their range is continually being extended.

Raw-Abutment® Holder

| Thanks to the easily installable Raw-Abutment® Holder, the titanium abutment blanks Raw-Abutment® can now also be processed with the Milling Units M1 Wet Heavy Metal, M2 Wet Heavy Metal, M2 Dual Wet Heavy Metal and M5 Heavy. Hence it is now also possible to create individual and extremely precise-fitting abutments of a high-quality medical titanium alloy (Ti-6Al-4V ELI according to ASTM F136 and DIN EN ISO 5832-3) with your own CAD/CAM device, in only 20 minutes. Due to the production in your own laboratory, you not only expand the service spectrum of your CAD/CAM device - leading to enormous time savings and an increased added value of your laboratory - but you can also even better guarantee the quality of your products, having actively participated in the production process. |  |

Raw-Abutment® Holder 6 Teleskoper

| Thanks to the Raw-Abutment® Holder 6 Teleskoper (⌀ 125 mm) it is now possible to mill up to 6 Raw-Abutments® in just one process with the extra-large Teleskoper Orbit in the M2 Teleskoper, M2 Dual Teleskoper and M2 Dual Double Teleskoper Milling Units. Due to the production in your own laboratory, you not only expand the service spectrum of your CAD/CAM device - leading to enormous time savings and an increased added value of your laboratory - but you can also even better guarantee the quality of your products, having actively participated in the production process. |  |

Titanium Spectral-Colouring Anodizer

|

With the Titanium Spectral-Colouring Anodizer the Raw-Abutment® can be anodised in the desired colour (e.g. golden), to prevent the metal from shining through the zirconia structure. This leads to even more natural and individually aesthetical restorations. |

Instruction

|

Titan abutments polishing Date of publication: January 2016 |

|

|

Overview of all currently available Raw-Abutment®