|

The specialization course about metal telescopes and partial dentures

| Target group: | Zirkonzahn zirconia and system users | ||

| Course duration: | 2 days | ||

| Participants: | 4 | ||

| Venue: | Zirkonzahn Education Center Brunico, Education Center Neuler other venues on request | ||

|

Preparation in the lab: |

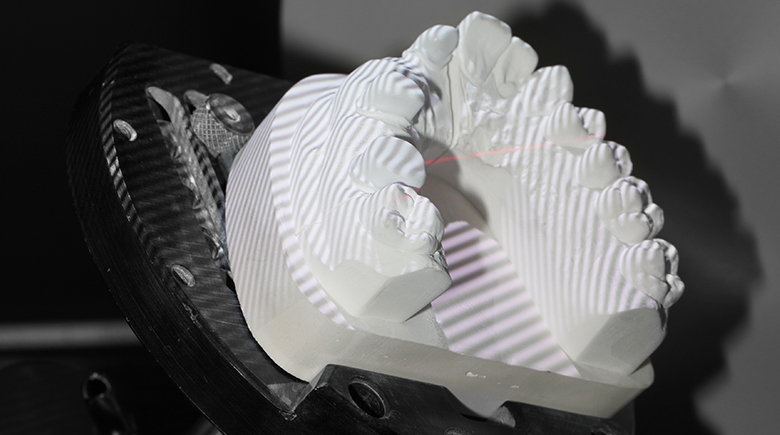

Parallelisation of two primary parts; will be delivered before the course starts | |

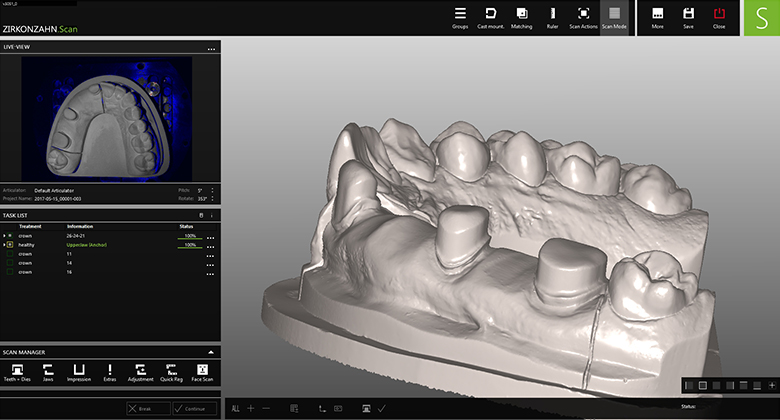

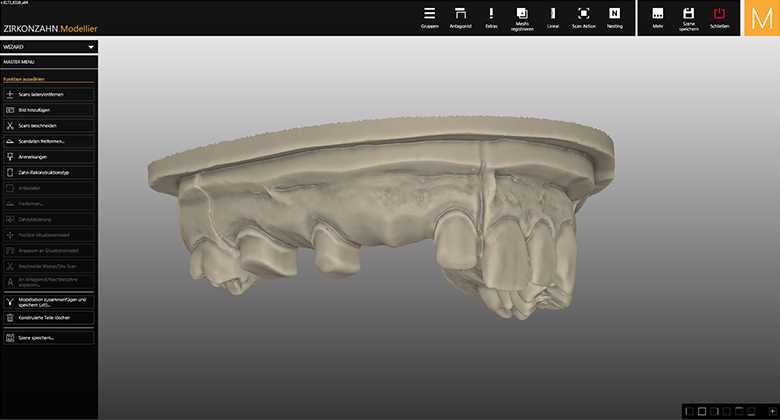

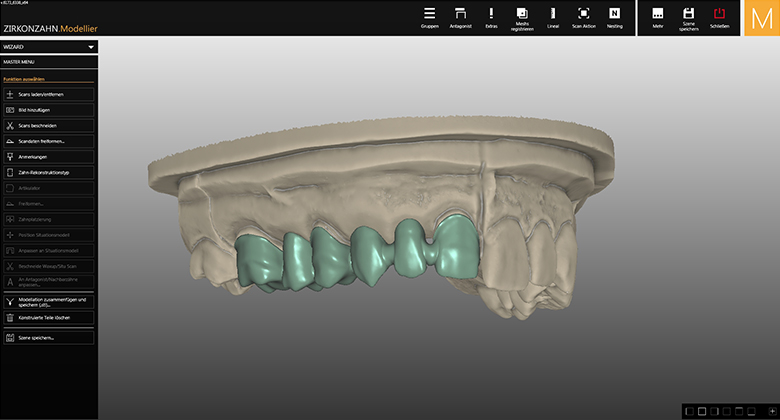

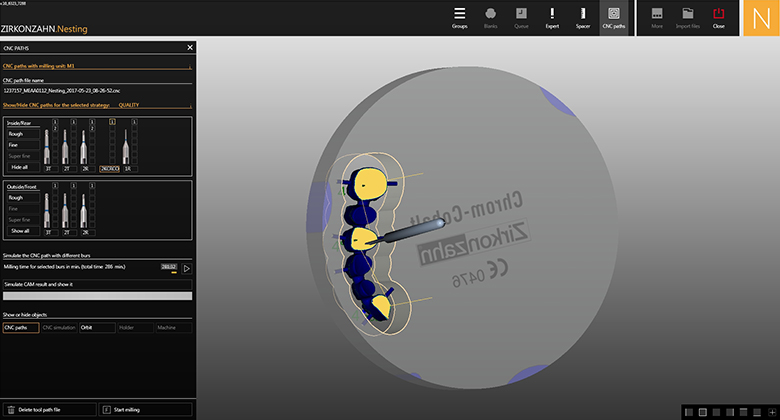

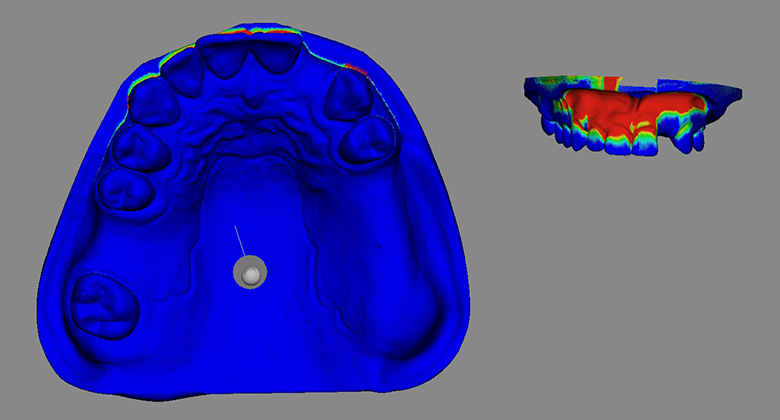

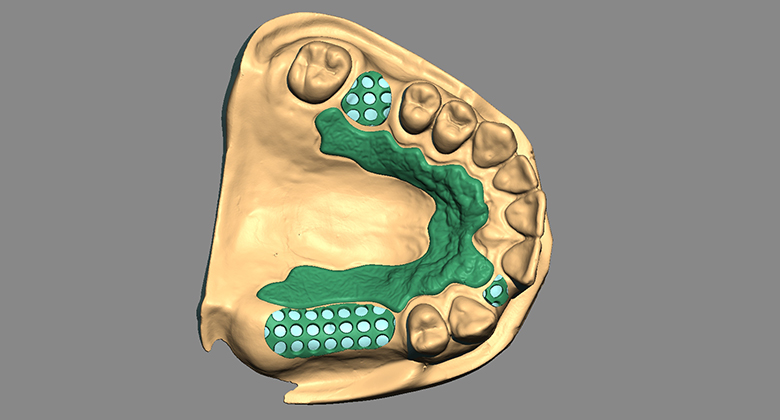

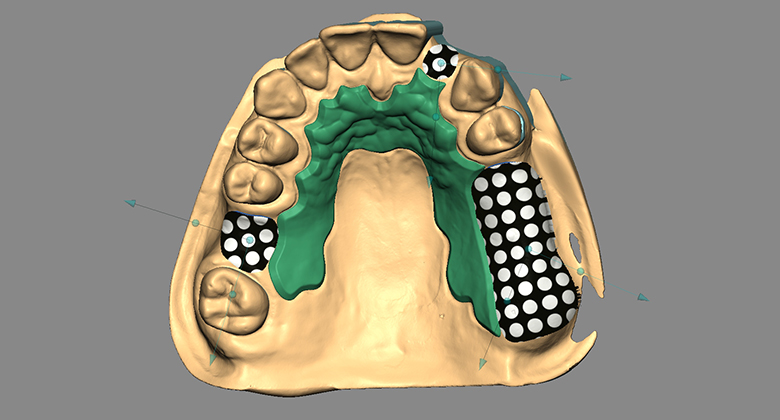

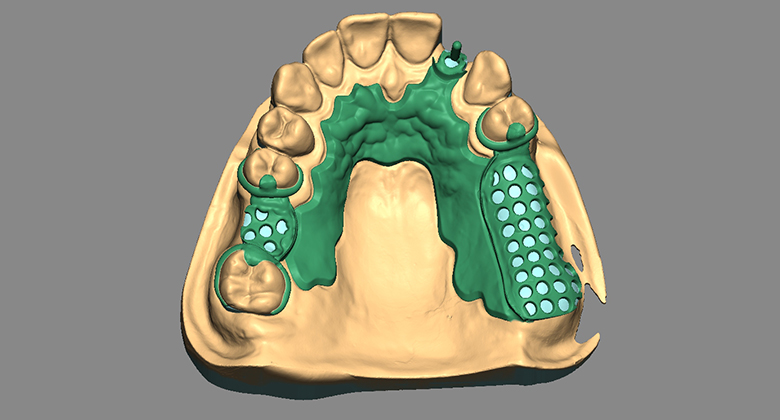

| Content: | We will explain you how to manufacture secondary telescopes with our S900 ARTI model scanner and with our milling units. The friction is already preset in the software. In the Zirkonzahn.Nesting software we adjust the parallel surface of the secondary telescopes individually. Due to the different dimensions of premolars, molars, front teeth and canines, individual friction settings are required for each tooth. In addition, you will design a partial denture with the Zirkonzahn.Partial-Denture software. |

Program

Day 1 (all-day)

- Scanning and designing of the secondary structure with teeth

- Explanation of important parameters and their settings

- Positioning of the secondary telescopes in the chrome-cobalt blank “Special”

- Setting of the final fit parameters

- Verification of the milling paths

- Nesting and milling of a primary structure in the chrome-cobalt blank “Special”

- Designing a mandibular telescopic prosthesis with resin posterior teeth according to the “Stego principle”

Day 2 (all-day)

- Check of the milled secondary structures

- Check of the friction setting and, if necessary, mechanical finishing of the friction

- Insight into the Zirkonzahn.Partial-Planner software and designing a partial denture

- Design tips for the “Stego principle”

- Resolve outstanding issues

Please bring

|

Personal work equipment (e.g. magnifying glasses) as well as model with parallelised primary parts |

Education Center

*Również W Brunico Na Życzenie

Zapraszamy do Heldencampus, Laboratory Steger in Brunico, Zirkonzahn headquarters in Gais

|

Education Center Brunico* Południowego Tyrol – Włochy T +39 0474 066 650 education@zirkonzahn.com |

1wszy dzień: 08.30 – 18.00 2gi dzień: 08.30 –18.00 |

1000,00 € (plus VAT) | Instrukcje dojazdu (Angielski) |

|

|

||||

|

Education Center Neuler Neuler – Niemcy T +49 7961933990 info@zirkonzahn.de |

1wszy dzień: 08.30 – 18.00 2gi dzień: 08.30 –18.00 |

1000,00 € (plus VAT) | Instrukcje dojazdu (Angielski) |

*Również W Brunico Na Życzenie

Zapraszamy do Heldencampus, Laboratory Steger in Brunico, Zirkonzahn headquarters in Gais

Podpisz teraz online

Chętnie pomożemy uczestnikom naszych kursów zarezerwować nocleg.

ZIRKONZAHN EDUCATION

Phone +39 0474 066 650 | F +39 0474 066 661 | education@zirkonzahn.com

ZIRKONZAHN EDUCATION

Phone +39 0474 066 650 | F +39 0474 066 661 | education@zirkonzahn.com