Cocronit Superior - Informacja o produkcie

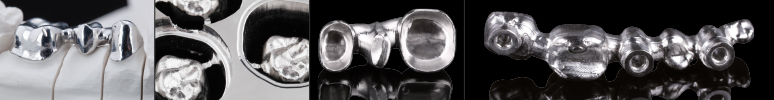

Zirkonzahn Cocronit Superior jest jednocześnie twardy i elastyczny. Dlatego też szczególnie nadaje się do produkcji belek i struktur metalowych do licowania ceramiką. Ponadto już istniejące uzupełnienia można odpowiednio powiększać dzięki dobrej lutowności tego materiału.

|

Info: od 21 kwietnia 2022 roku nasz Chrom-Cobalt ma nową nazwę: Cocronit Superior.

Właściwości i zakres zastosowań pozostają bez zmian. |