NOVOZirkonofen Turbo

ZIRKONOFEN TURBO - A NEW ERA BEGINS

| Driven by diligence, dedication and enthusiasm, we strive tirelessly to give our clients always and only the best. We are aware of their requirements and we know our ambitions. It is the union of these two aspects that leads us to the best results. We never overlook any detail, searching for new solutions with meticulous attention until the finest point is set – only then can we be truly proud of our product. Our constant search for perfection and innovation drives us day by day and we do not know what the word "rest" means. No challenge is too tough for us and we have proved it again. |

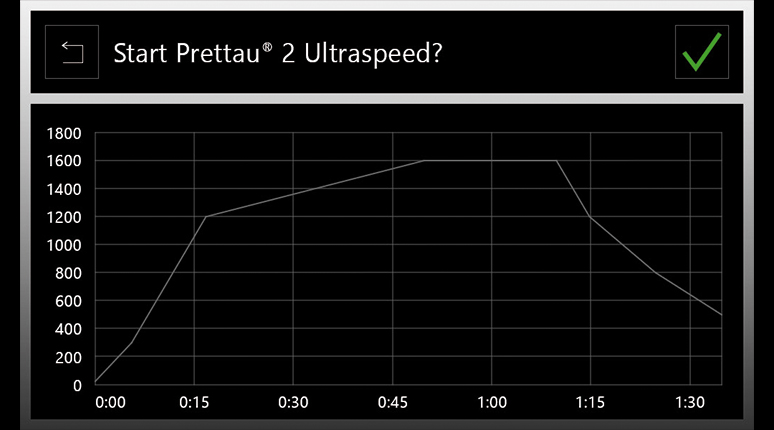

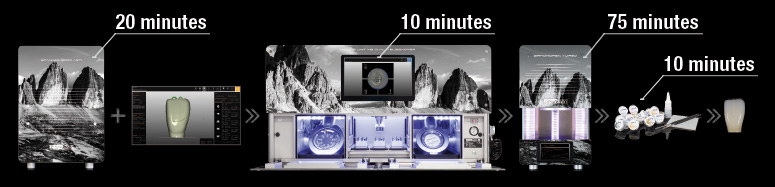

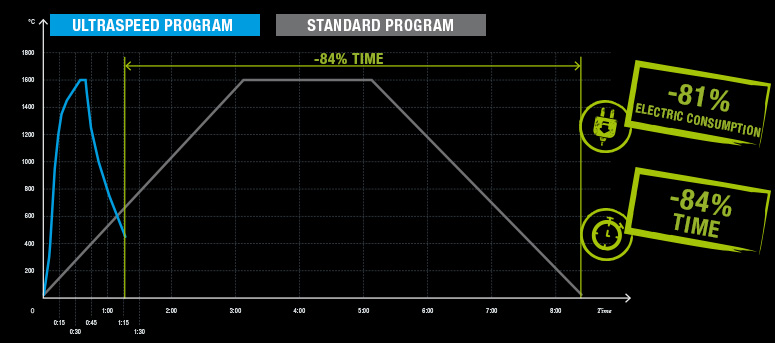

With the new Zirkonofen Turbo and its pre-set fast sintering programs for each kind of Zirkonzahn zirconia, it is now possibile to sinter smaller zirconia structures in about 75 minutes. This cuts processing time by 84% and reduces electric consumption by 81%: zirconia structures can be milled, sintered and veneered in 1 hour and 55 minutes only!

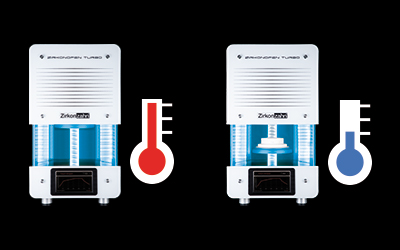

The sintering platform is controlled by an intelligent electronic system developed in-house. This system monitors the temperature curve of the sintering chamber and controls the platform during the cooling phase.

|

If the sintering chamber does not cool down quickly enough, the platform moves automatically downwards, ensuring optimal cooling processes and perfect sintering results. |

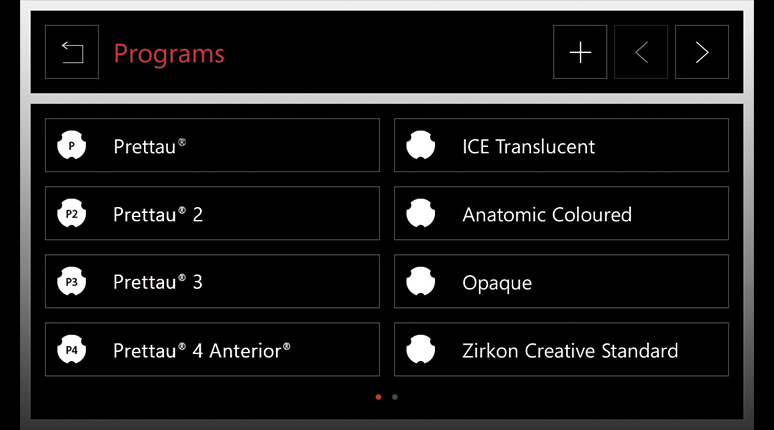

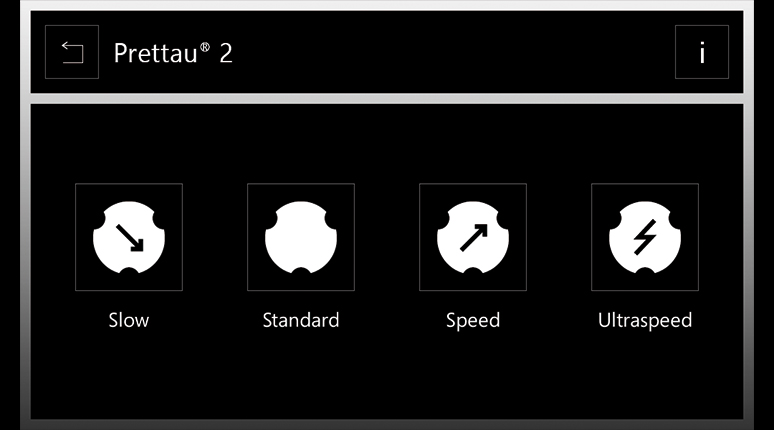

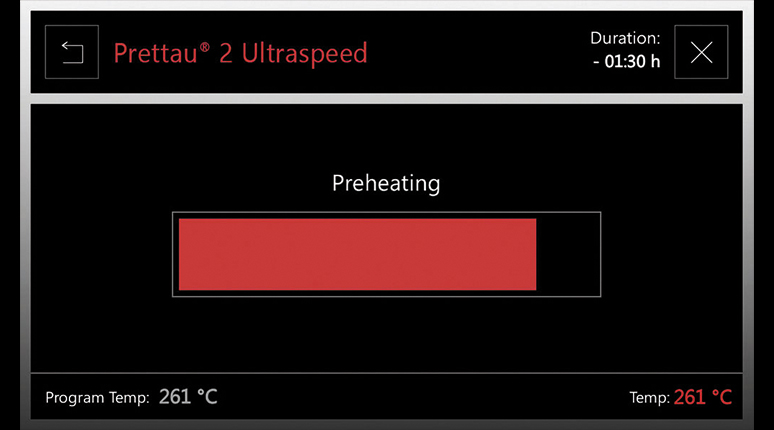

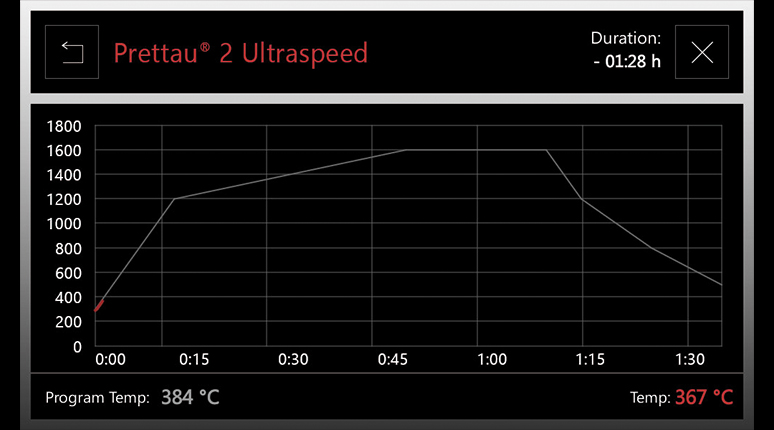

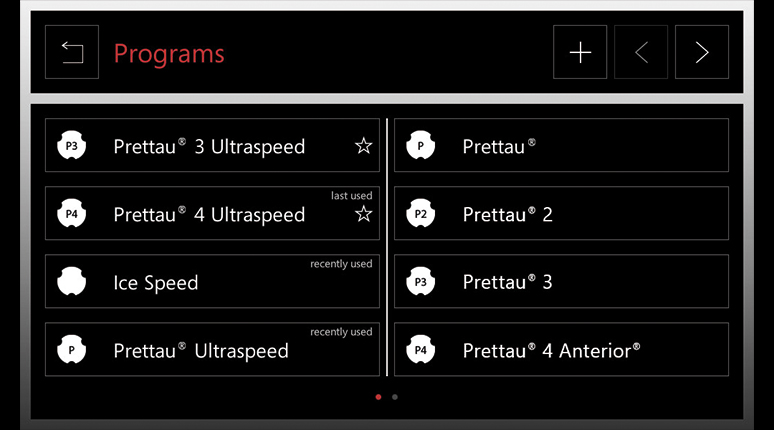

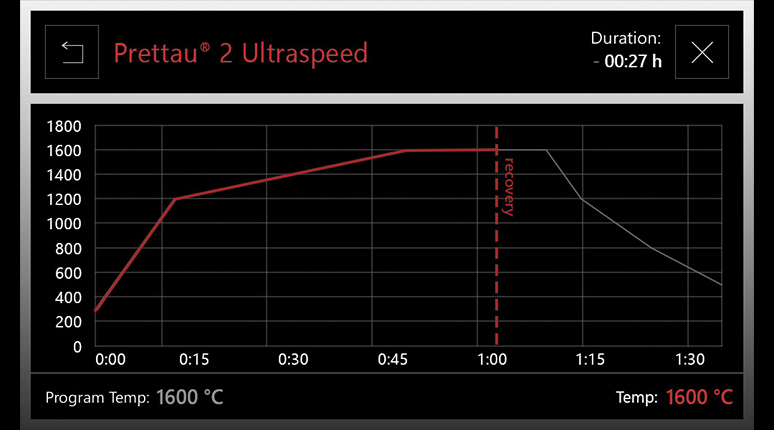

SINTERING PROGRAMS

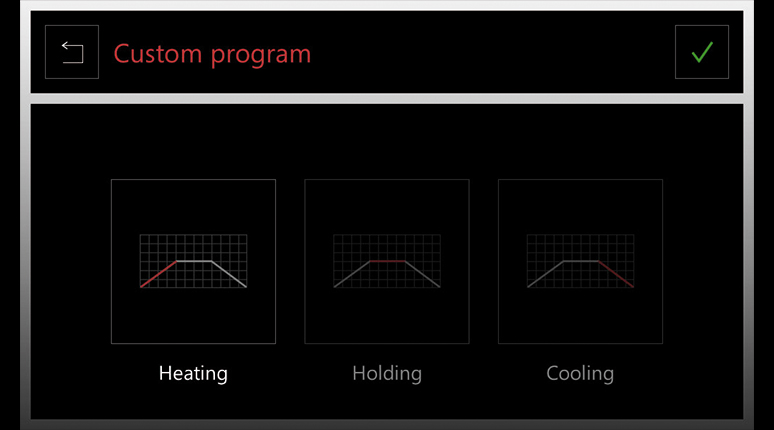

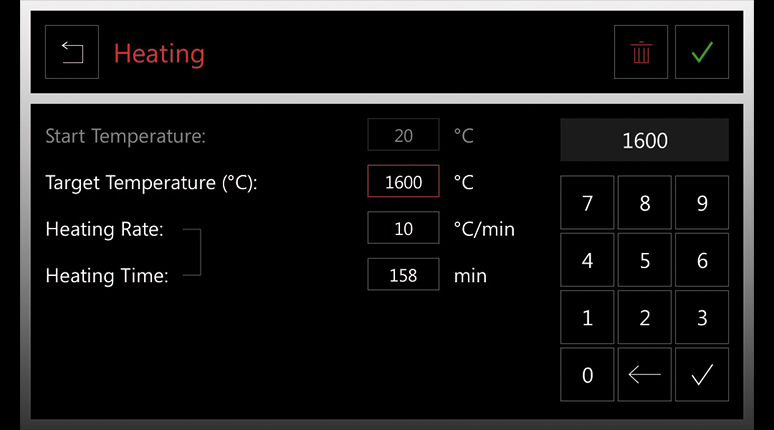

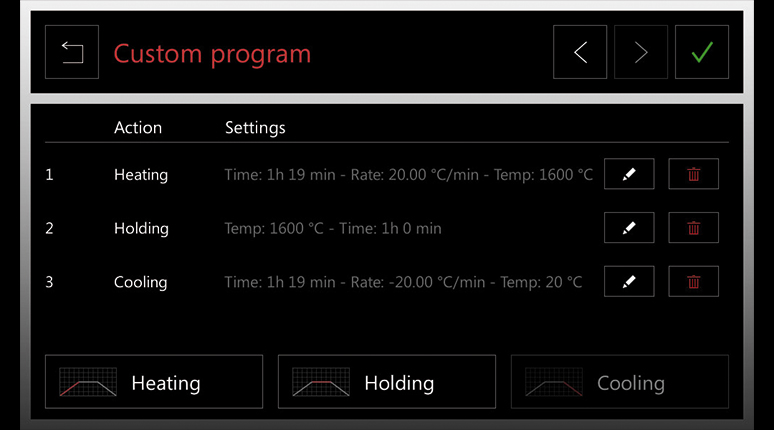

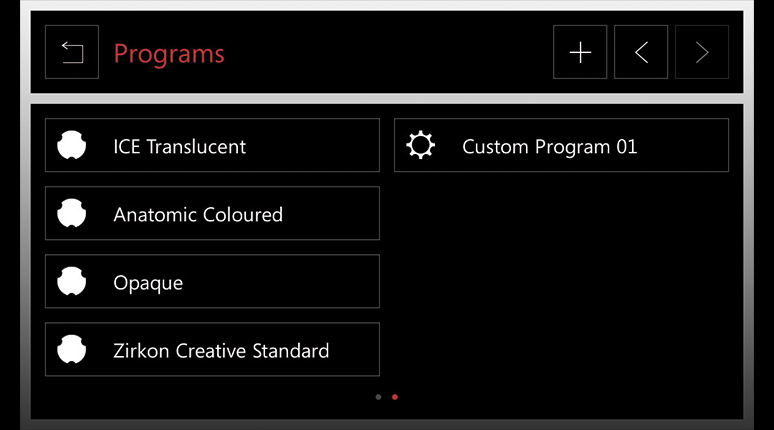

The Zirkonofen Turbo includes a large number of pre-set programs that are perfectly matched to each kind of Zirkonzahn zirconia. This means that the heating, holding and cooling phases vary slightly depending on the material. In addition, the user can create personal sintering programs.

The Speed and Ultraspeed programs cannot be used for sintering dental unit with a wall thickness exceeding 4 mm. Therefore, when selecting the sintering speed, attention must be paid to the elements' wall thickness and weight.

| Personalised programs according to | ||||||

| the following parameters: | ||||||

| Temperature range | Heating rate | |||||

| Room temperature – 300 °C | 50 °C/min | |||||

| 300 °C – 1100 °C | 120 °C/min | |||||

| 1100 °C – 1700 °C | 60 °C/min | |||||

| Temperature range | Cooling rate | |||||

| 1700 °C – 1200 °C | 60 °C/min | |||||

| 1200 °C – 800 °C | 40 °C/min | |||||

| 800 °C – Room temperature | 30 °C/min | |||||

|

SLOW PROGRAM – 12 H | heavy | ≥ 5 g per unit | |||

|

STANDARD PROGRAM – 8 H | medium heavy | 3-5 g per unit | |||

|

SPEED PROGRAM – 3,5 H | light | 2-3 g per unit | |||

|

ULTRASPEED PROGRAM – 75 min | super light | ≤ 2 g per unit | |||

|

||||||

|

Shortest program – 45 min | |||||

|

Large number of pre-set programs | |||||

|

Personalised sintering programs | |||||

| The Zirkonofen Turbo is equipped with pre-set fast sintering programs perfectly adapted to each Zirkonzahn zirconia material. The smaller and thinner the structure to be sintered, the shorter the required sintering time. With this furnace, 4-unit bridges can now be sintered in approx. 75 minutes. |

Baking Recovery

|

With the new Baking Recovery function, unsatisfactory sintering results are nearly impossible! After a power failure, the intelligent software checks whether the sintering program can be regularly completed without compromising the result orr whether the sintering process must be must be suspended. If the sintering program can be continued, the user can see on the screen in which phase of the program the interruption occurred. If the program cannot be completed, the software will inform the user. |

CAPACITY

| In the Zirkonofen Turbo, zirconia restorations can be sintered by means of special accessories, like the sintering trays and the ceramic plate. The sintering chamber can contain up to 3 sintering trays stacked on top of each other, which permit sintering up to 120 zirconia elements in one single process. If bridges are sintered with a sintering stabiliser, the ceramic plate must be used, which offers space for up to 3 full-arch bridges. | ||||

|

|

|

||

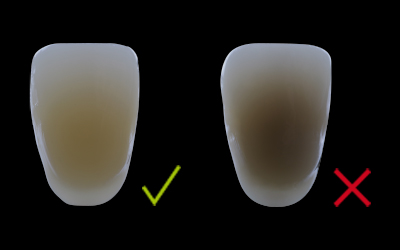

| To avoid pressure marks on the zirconia elements during sintering, the elements must be placed on the sintering tray well apart from each other. To prevent discolouration, the base of the sintering tray should be covered with sintering granules. | The sintering chamber contains up to 3 sintering trays stacked on top of each other. In this way, up to 120 zirconia elements can be sintered in one sintering process. | To prevent discolouration or contamination of zirconia structures during the sintering process, it is recommended to cover the bridges with a ceramic protection cover. The new ceramic protection cover, with its curved shape, guarantees optimal heat distribution. | ||

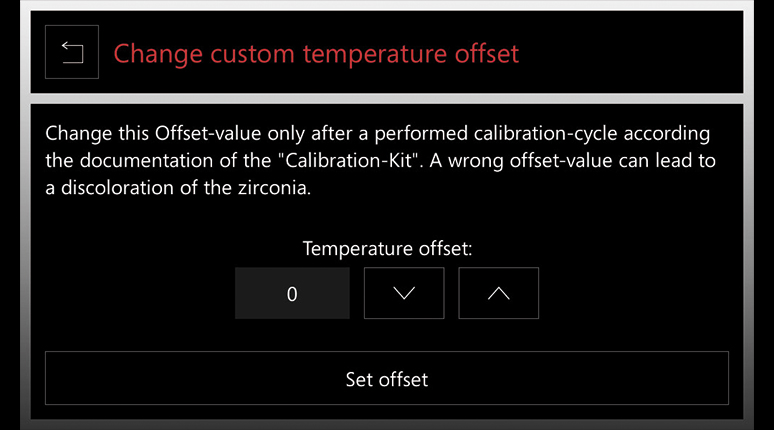

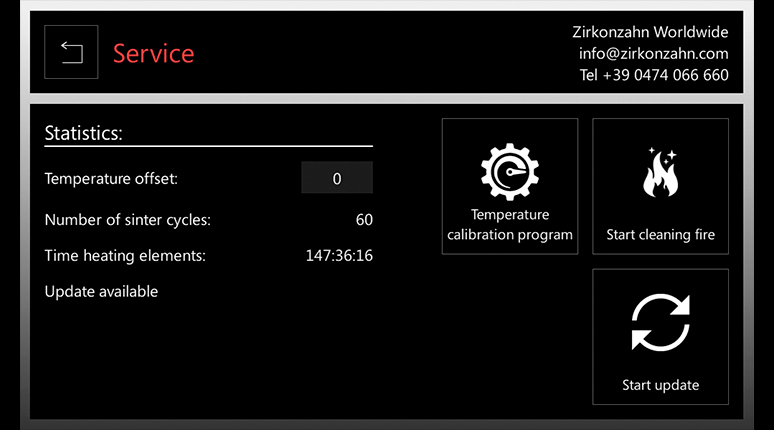

TEMPERATURE CALIBRATION

| Every Zirkonofen Turbo is optimally calibrated before delivery, in order to achieve the best sintering results right from the first usage. Thanks to the temperature calibration program, the user can check at any time the oven's temperature control accuracy of +/- 2 °C at a final temperature of 1600 °C. If necessary, values can be corrected directly in the software. | ||||

|

|

|

||

| 1. Place the temperature calibration ring without using firing supports on the sintering platform and start the temperature calibration program | 2. Let the ring cool down to room temperature and measure the diameter with a micrometer screw | 3. Compare the measured value with the reference table and enter the difference in the software. Perform a second temperature calibration to check the final sintering temperature | ||

|

To obtain the highest quality results with unchanged translucency, colour gradient or flexural strength values, it is essential to adapt the sintering program to the material and to the structure to be sintered. If parameters are correct but the results are still unsatisfactory, a temperature calibration must be carried out. |

|||

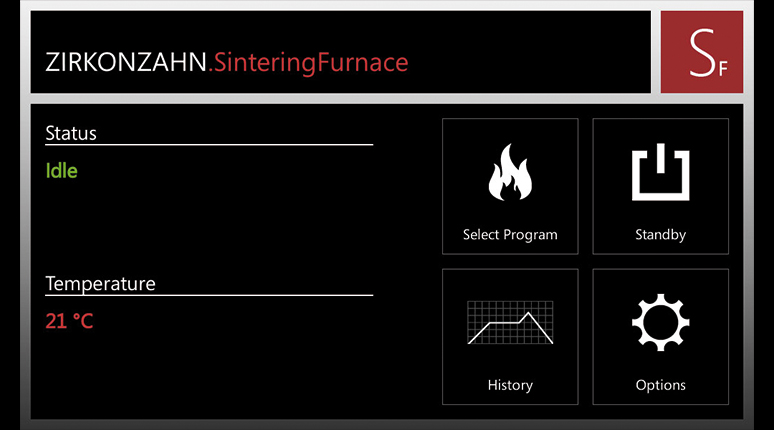

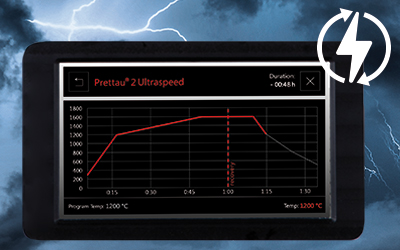

Software

The software, developed in-house, has been re-designed especially for the Zirkonofen Turbo.

A wider range of languages is now available to the users. Via the Internet connection, they can download and install updates directly in the furnace, in order to always work with the latest functions and sintering programs. The software also permits creating individual sintering programs in addition to the pre-set ones and, based on the user behaviour, it recognises the most frequently used programs and saves them as favourites, for an easier selection when starting a new sintering cycle.

LED LIGHTING WITH STATUS DISPLAY

| The four different coloured displays show at a glance the current status of the Zirkonofen Turbo: | ||||||

|

|

|

|

|||

| Green = idle mode ready for a sintering process |

Purple = heating and holding phase the sintering process is underway |

Light blue = cooling phase the sintering chamber is being cooling down |

Red = error a problem has occurred |

|||

DOWNLOAD BROCHURE

|

Our long-standing experience in the development of CAD/CAM milling units, scanners and sintering furnaces makes us the experts in this field. With innovation and strong willpower, we develop holistic products that are perfectly integrated into the Zirkonzahn workflow. With the Zirkonofen Turbo, we start a new era together. |

|||

|

Brochure Zirkonofen Turbo sintering furnace | |||

OVERVIEW OF THE CHARACTERISTICS

|

Turbo sintering of zirconia in 75 min |  |

Heating rate of up to 120 °C/min possible | ||||||||

|

Round sintering chamber with room for up to 120 zirconia elements |

|

Cooling rate of up to 60 °C/min possible | ||||||||

|

4 MoSi2 high-performance heating elements |  |

Automated cooling through fully automatic sintering platform | ||||||||

|

Large sintering chamber with a capacity of 0.9 l |  |

Maximum sintering temperature of 1700 °C | ||||||||

|

Over 1000 min. sintering time per program |  |

Control accuracy of +/- 2 °C at a final temperature of 1600 °C | ||||||||

|

Baking Recovery Function |  |

Independent temperature calibration | ||||||||

|

7“ colour touch screen |  |

Large number of pre-set programs | ||||||||

|

New, user-friendly software |  |

Personalised sintering programs | ||||||||

|

Update via LAN or WIFI |  |

Compact, modern design with high-quality full glazing | ||||||||

TECHNICAL DATA:

| Size (W x H x D) | 39 x 69 x 49 cm | |

|

|

|

|

| Weight | 65 kg | |

|

|

|

|

| Electrical power | 3000 W | |

|

|

|

|

| Mains voltage | 200 - 240 V~ ± 10%V/ 50 - 60 Hz |

|

|

|

|

|

| Combustion Chamber Capacity | 0,9l | |

|

|

|

|

| Large sintering chamber | 10,5 x 10,5 ⌀ cm | |

|

|

|

|

| Max. temperature | 1700° C | |

|

|

|

|

| Vacuum | No | |

|

|

|

|

| Capacity | Up to 120 zirconia elements (with sintering tray) or up to 3 circular bridges (with ceramic plate) |

|

||||

|

|

|

|

|

| Mirror | Orange | Red | Black | |

Accessories

|

Novo! Sintering tray Speed Zirkonofen Turbo The trays have been specially designed to ensure perfect heat distribution during sintering and for use in combination with the Ultraspeed program. Up to 3 sintering trays can be placed in the furnace. In this way up to 120 zirconia elements can be sintered in one sintering process. Número do produto: ZBAA3221 |

|

|

Novo! Ceramic plate Zirkonofen Turbo Sintering support to avoid contact stains on the framework. It can contain max. 3 full-arch bridges. It cannot be used with the Ultraspeed program. Número do produto: ZBAA9441 |

|

|

Novo! Ceramic protection cover Zirkonofen Turbo For optimal colour fidelity of the zirconia structures during sintering. The curved shape serves for optimal heat distribution inside the protection cover. It cannot be used with the Ultraspeed program. Número do produto: ZBAA4671 |

|

|

Novo! Temperature calibration ring for Zirkonofen Turbo Content: 10 rings for temperature calibration of the Zirkonofen Turbo sintering furnace. A micrometer screw (or similar) to measure the ring diameter is required. Número do produto: ZBAC9081 |

|

|

Novo! Tweezers for Zirkonofen Turbo Stainless steel tweezers for removing the sintering tray from the sintering chamber (included). Número do produto: ZBAC9082 |

|

|

Fine-grain sintering granules Sintering powder for sintering zirconia structures with sintering trays. Size: 0.4 mm – 1.0 mm Número do produto: ZBAA3251 |

|

|

Coarse-grain sintering granules Sintering powder for sintering zirconia structures with sintering trays. Size: 0.3 mm – 2.0 mm Número do produto: ZBAA3261 |

SINTERING SPEEDS

Sintering speeds that can be selected using the different sintering furnaces.

| hours |  |

|

|

|

|

|||||||||||||||||||||||||||||||

| 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

Zirkonofen

600/V3

|

Zirkonofen 700 |

Zirkonofen Ultra-Vakuum |

Zirkonofen Turbo |

Sinterofen 300S |

|||||||||||||||||||

| SLOW | ||||||||||||||||||||||||||||||||||||

|

|

|

|

|

||||||||||||||||||||||||||||||||

| STANDARD | ||||||||||||||||||||||||||||||||||||

|

|

|

|

|

||||||||||||||||||||||||||||||||

| SPEED | ||||||||||||||||||||||||||||||||||||

|

|

|

|

|

||||||||||||||||||||||||||||||||

| ULTRA-SPEED | ||||||||||||||||||||||||||||||||||||

|

|

|

|

|

||||||||||||||||||||||||||||||||

| METAL SINTERING | ||||||||||||||||||||||||||||||||||||

|

|

|

|

|

||||||||||||||||||||||||||||||||