Fresadora M2 Wet Heavy Metal

M2 milling unit comfort line – Fully automatic, flexible, open

The new M2 milling unit comfort line stands for modern operating comfort and flexibility. With the M2 Wet Heavy Metal, the M2 Teleskoper, the M2 Dual Wet Heavy Metal, the M2 Dual Teleskoper and the M2 Dual Double Teleskoper, the comfort line comprises five milling units with fully automatic 5+1 axis simultaneous milling technology. The highlight in terms of flexibility is the extra-large Teleskoper Orbit (⌀ 125 mm) that, in combination with special holders, permits to process all common soft and hard material blanks of ⌀ 95 mm, ⌀ 98 mm, ⌀ 106 mm or even ⌀ 125 mm. With the Teleskoper Orbit blanks can be removed and reinserted back into the orbit at exactly the same position with a precision in μm range. This is particularly helpful for adjusting the friction of telescopic jobs or for the two-stage fabrication of immediate restorations in case of implant-supported prostheses (with the double milling technique). All M2 milling units are stand-alone solutions: it is possible to start milling and calibration processes or load elaboration tools directly from the machine via the integrated PC with touchscreen. The optical tool detection ensures greater safety during milling. The two separate large milling chambers are the trademark of the M2 Dual milling units. However, also the M2 and the M2 Telescoper milling units are characterised by spaciously designed, optimally illuminated and easily accessible milling chambers as well as with a separated, contamination-protected tool chamber with 21-compartment automatic tool changer (optional up to 3 x 21 for the M2 Dual versions) The automatic self-cleaning function, the integrated Cleaning Kit for an easy cleaning of the milling chambers and the Ioniser (optional) ensure a particularly clean elaboration of the materials. The performance range of the machines can be extended by integrating different accessories available, e.g. the Glass Ceramic/Raw-Abutment® Holder and the JawPositioner Support. With the M2/M2 Dual Upgrade Kit, the M2 Wet Heavy Metal and the M2 Dual Wet Heavy Metal milling units can be upgraded to the Teleskoper version.

Features at a glance

- Open milling units with Teleskoper Orbit ⌀ 125 mm or Orbit ⌀ 95 mm

- Stand-alone milling units: Integrated PC with touch screen for direct control (loading of tools, controlling of milling and calibration processes)

- Fully automated 5+1 axis simultaneous milling technology

- High-performance milling spindle with optimised cooling water supply for particularly gentle material elaboration

- Wet and dry processing of all common dental materials (zirconia, resin, wax, Sintermetall, cobalt-chrome, titanium, Raw-Abutments®, glass-ceramics and composite).

- Spaciously designed, optimally illuminated and easily accessible milling chambers

- Contamination-protected tool chamber, which is separated from the milling chamber, with automatic 21-compartment tool changer function

- Optical tool detection for a secure selection of the suitable milling tools

- Integrated space for the organised storage of additional tool magazines, with 21 tool slots each (63 and 84 slots in total)

- Automatic self-cleaning and drying function and Cleaning Kit for manual cleaning

- The Ioniser (optional) ensures clean resin processing with a significantly shorter cleaning time

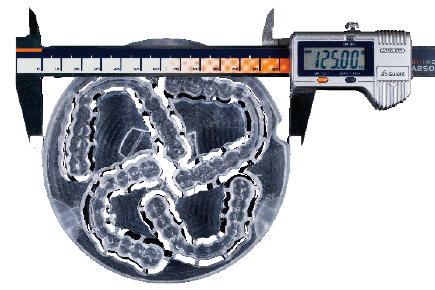

- Teleskoper Orbit ⌀ 125 mm (available for the versions M2 Teleskoper, M2 Dual Teleskoper and M2 Dual Double Teleskoper): in combination with special holders, material blanks with a diameter of ⌀ 95 mm, ⌀ 98 mm, ⌀ 106 mm or even ⌀ 125 mm can be elaborated. Blanks can be removed and can be reinserted back into the orbit at exactly the same position with a precision in μm range, e.g. for the adjustment of the friction and for Double Milling

NovoExtra large Teleskoper Orbit (⌀ 125 mm)

| ⌀ 95 |

2

|

36

|

25

|

2 bite splints 36 resin elements 25 zirconia elements |

||||

| ⌀ 98 |

2

|

34

|

23

|

2 bite splints 34 resin elements 23 zirconia elements |

||||

| ⌀ 106 |

3

|

44

|

31

|

3 bite splints 44 resin elements 31 zirconia elements |

||||

| ⌀ 125 |

4

|

57

|

4 bite splints 57 resin elements |

|||||

| Bite splints | Resin | Zirconia | ||||||

| The highlight in terms of flexibility is the extra-large Teleskoper Orbit (⌀ 125 mm). In combination with special holders, it permits to process all common soft and hard material blanks with ⌀ 95 mm, ⌀ 98 mm, ⌀ 106 mm or even ⌀ 125 mm as well as glass-ceramic and Raw-Abutment® blanks. The blanks can be removed from the orbit and re-inserted later into the orbit at the same position with high precision in µm range. | ||||||||

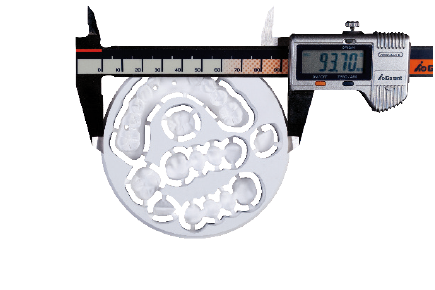

Blank with ⌀ 106 mm

Blank with ⌀ 106 mm - 24 % larger milling surface

Friction

Adjusting the friction of telescopic works created with the milling units of the M2 milling unit series with Teleskoper Orbit

Double Milling

Double Milling with milling units of the M2 milling unit series with Teleskoper Orbit: Time-saving milling of implant-supported restorations

* The M2 Teleskoper, M2 Dual Teleskoper and M2 Dual Double Teleskoper are equipped by default with the extra large Teleskoper Orbit (125 mm). In the M2 Wet Heavy Metal and the M2 Dual Wet Heavy Metal, the orbit ⌀ 95 mm is installed. The Teleskoper Orbit can be retrofitted in these milling units with an upgrade kit.

Comparison of the Characteristics

M2 Wet Heavy Metal |

M2 Teleskoper |

M2 Dual Wet Heavy Metal |

M2 Dual Teleskoper |

M2 Dual Double Teleskoper |

|||

|---|---|---|---|---|---|---|---|

|

Equipment

|

Fully automated 5+1 axes simultaneous milling technology | ||||||

| Wet and dry processing | |||||||

| Hard and soft materials | |||||||

| Tool changer: automatic tool exchange function | |||||||

| Tool storage: Tool chamber with slots for elaboration tools | |||||||

| Tool Detector: optical tool detection | |||||||

| Stand-alone: Control via touchscreen directly on the milling unit | |||||||

| Self-cleaning: Automatic self-cleaning and drying function | |||||||

| Cleaning Kit for manual cleaning | |||||||

| Ioniser: discharge of plastic shavings for a clean milling process | |||||||

| 2 separated milling chambers for flexible production | |||||||

|

|

|||||||

|

Orbit

|

Orbit ⌀ 95 mm | ||||||

| Teleskoper orbit (⌀ 125 mm): with clamping rings for the exact repositioning of material blanks with milled structures in the orbit | |||||||

|

|

|||||||

|

Compatible blanks

|

Material blanks ⌀ 95 mm (orbit ⌀ 95 or clamping ring) |

||||||

| Material blanks ⌀ 98 mm (with clamping ring) |

|||||||

| Material blanks ⌀ 106 mm (with clamping ring) |

|||||||

| Material blanks ⌀ 125 mm (without clamping ring) |

|||||||

| JawPositioner (clamping ring for 1 workpiece) |

|||||||

| Glass ceramic/composite (clamping ring for 4 or 9 workpieces) |

|||||||

| Raw-Abutment® (clamping ring for 3 or 6 workpieces) |

|||||||

| Glass ceramic/composite (clamping ring for 4 or 9 workpieces) |

|||||||

| Raw-Abutment® (clamping ring for 3 or 6 workpieces) |

|||||||

|

|

|||||||

|

Special

features |

Removal and repositioning of material blanks with an accuracy of 5 μm, e.g. for telescopes (adjustment of the friction) and Double Milling | ||||||

| * can be upgraded to Teleskoper or Double Teleskoper milling unit | |||||||

NOVO⌀ 125 mm for M2 milling unit series and M4 Wet Heavy Metal milling unit

|

|

2 x bite splints or 1 x full-arch 2 x 4-unit bridges 5 x single crowns |

⬐ Larger milling area with ⌀ 95 mm ⬎

|

|||

|

|

2 x bite splints or 1 x full-arch 2 x 4-unit bridges 4 x single crowns |

||||

|

|

3 x bite splints or 1 x full-arch 2 x 4-unit bridges 11x single crowns |

||||

|

|

4 x bite splints or 1 x full-arch 3 x 4-unit bridges 21x single crowns |

||||

⌀ 106 mm: Available for the most common materials (zirconia, resin, etc.)

⌀ 125 mm: Available for the most common resins