Burnout Cap

|

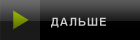

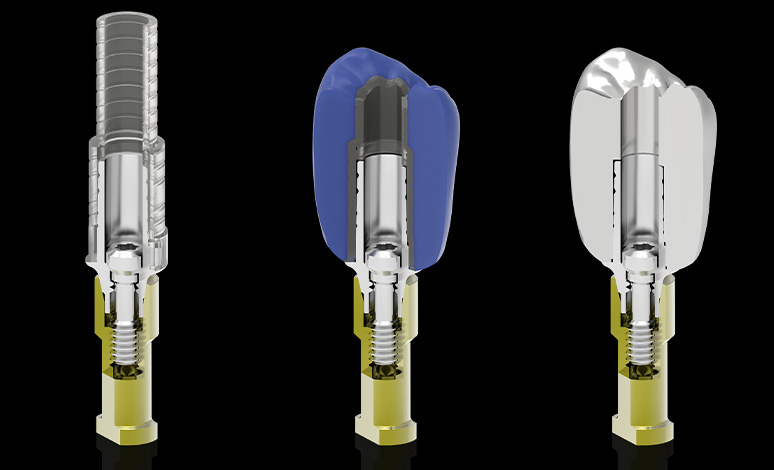

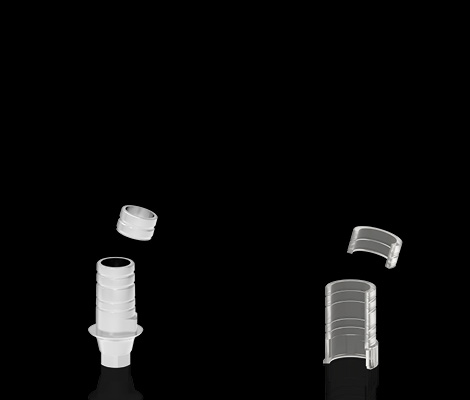

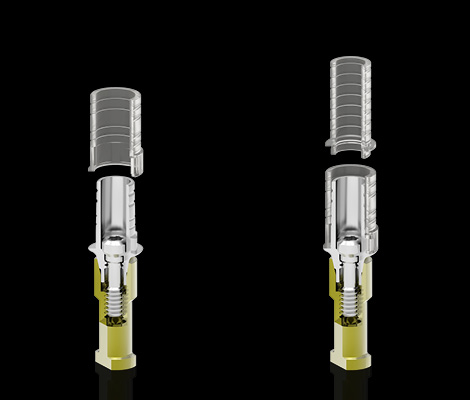

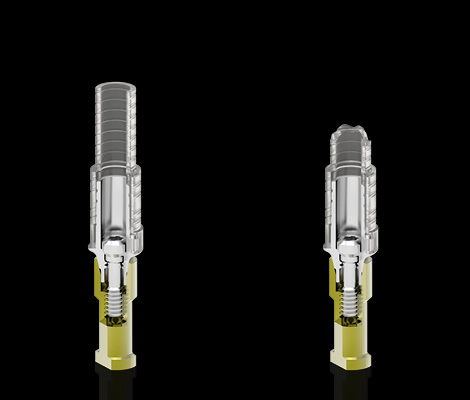

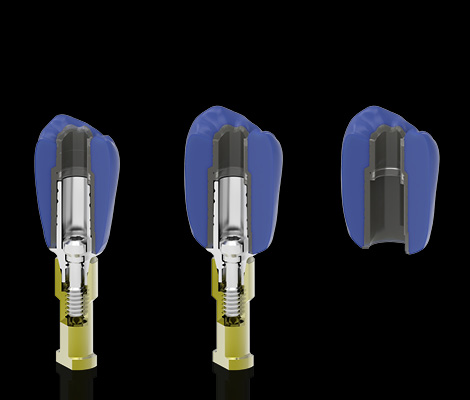

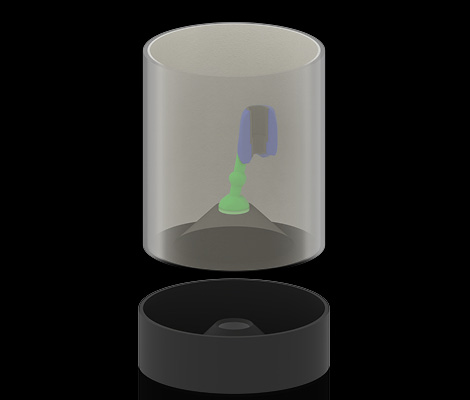

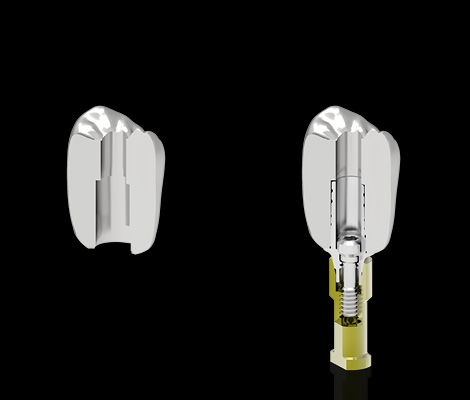

The Burnout Caps are burnout resin sleeves for modelling reconstructions with an incorporated screw channel. They are particularly suitable for laboratories that do not work with CAD/CAM systems but still want to achieve the highest precision in their restorations. Modelling the wax reconstruction on the resin sleeves, guarantees a perfect fit between the prosthesis and the titanium base after the burn-out process and subsequent casting or pressing. The Burnout Caps can be used on titanium bases K85 as well as on Zirkonzahn Multi Unit Abutments NON HEX and Multi Unit Abutments 17°. Since the titanium bases K85 can be individually shortened to the length of the restoration, these Burnout Caps are conceived in two parts and consist of a Burnout Cap Base and a Burnout Cap Extension. |

|

Compatibility overview of titanium bases K85 / Zirkonzahn Multi Unit Abutments NON HEX with the corresponding Burnout Caps |

Burnout Caps for conical titanium bases NON HEX K85

|

|

|

|

|

||||

диаметр: Ø 3.75 товарный номер: BCAD3750K85 В ближайшее время

|

диаметр: Ø 4.00 товарный номер: BCAD4000K85 |

диаметр: Ø 4.25 товарный номер: BCAD4250K85 |

диаметр: Ø 4.50 товарный номер: BCAD4500K85 В ближайшее время

|

диаметр: Ø 4.75 товарный номер: BCAD4750K85 |

|

|

|

|

|

||||

диаметр: Ø 5.00 товарный номер: BCAD5000K85 |

диаметр: Ø 5.25 товарный номер: BCAD5250K85 |

диаметр: Ø 5.50 товарный номер: BCAD5500K85 В ближайшее время

|

диаметр: Ø 5.75 товарный номер: BCAD5750K85 |

диаметр: Ø 6.00 товарный номер: BCAD6000K85 В ближайшее время

|

|

|

|

|

|

||||

диаметр: Ø 6.25 товарный номер: BCAD6250K85 |

диаметр: Ø 6.50 товарный номер: BCAD6500K85 В ближайшее время

|

диаметр: Ø 6.75 товарный номер: BCAD6750K85 В ближайшее время

|

диаметр: Ø 7.00 товарный номер: BCAD7000K85 В ближайшее время

|

диаметр: Ø 7.25 товарный номер: BCAD7250K85 |

Burnout Caps for parallel titanium bases HEX K85

|

|

|

|

|

||||

диаметр: Ø 3.75 товарный номер: BCAB3750K85 В ближайшее время

|

диаметр: Ø 4.00 товарный номер: BCAB4000K85 |

диаметр: Ø 4.25 товарный номер: BCAB4250K85 |

диаметр: Ø 4.50 товарный номер: BCAB4500K85 |

диаметр: Ø 4.75 товарный номер: BCAB4750K85 |

|

|

|

|

|

||||

диаметр: Ø 5.00 товарный номер: BCAB5000K85 |

диаметр: Ø 5.25 товарный номер: BCAB5250K85 |

диаметр: Ø 5.50 товарный номер: BCAB5500K85 В ближайшее время

|

диаметр: Ø 5.75 товарный номер: BCAB5750K85 |

диаметр: Ø 6.00 товарный номер: BCAB6000K85 |

|

|

|

|

|

||||

диаметр: Ø 6.25 товарный номер: BCAB6250K85 |

диаметр: Ø 6.50 товарный номер: BCAB6500K85 В ближайшее время

|

диаметр: Ø 6.75 товарный номер: BCAB6750K85 В ближайшее время

|

диаметр: Ø 7.00 товарный номер: BCAB7000K85 В ближайшее время

|

диаметр: Ø 7.25 товарный номер: BCAB7250K85 |

Burnout Caps for Zirkonzahn Multi Unit Abutment

|

|

|

|

|

||||

Zirkonzahn MUA товарный номер: BCAH9231 |

Burnout Caps – Step by Step

|

Adjust the Burnout Cap Base to the length of the titanium base (see instructions). | |

|

Screw the titanium base to the laboratory analogue. | |

|

Place the Burnout Cap Base on the titanium base. Insert the Burnout Cap Extension into the Burnout Cap Base through the top. | |

|

Shorten the Burnout Cap Extension to the individual length of the antagonist. | |

|

Model the wax reconstruction around the Burnout Cap. Remove the final wax model together with the Burnout Cap from the titanium base. | |

|

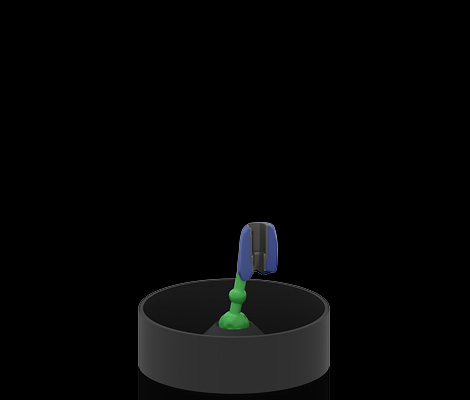

Provide the reconstruction with casting channel (preferably with reservoir) and fix it to the casting tray. | |

|

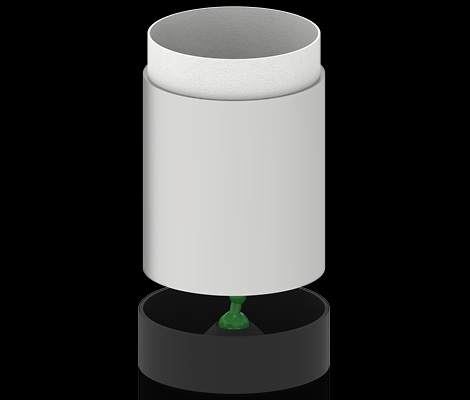

Put the casting ring (if necessary with liner) on the wax model. | |

|

Fill the casting ring with investment material and let it harden (follow the instructions of the respective manufacturer). Attention: avoid air pockets! |

|

|

Remove the casting tray and, if necessary, the outer ring before burning out. Heat the casting ring until the wax is completely burnt out (observe the heating parameters in the manufacturer's instructions for the investment material and the metal used). |

|

|

After reaching the preheating temperature, fill the cavity with metal (follow the respective manufacturer's instructions). Alternatively, pressed ceramics can also be used (observe manufacturer's instructions for processing). |

|

|

Remove the investment material from the reconstruction and cut off the casting channel with a cutting disc. | |

|

Finish the reconstruction with different tools (e.g. tungsten carbide burs, rubber polishers) and veneer with ceramic if necessary. After finishing, the titanium base is cemented to the reconstruction. |