NEWM2 Teleskoper milling unit

Overview of the characteristics

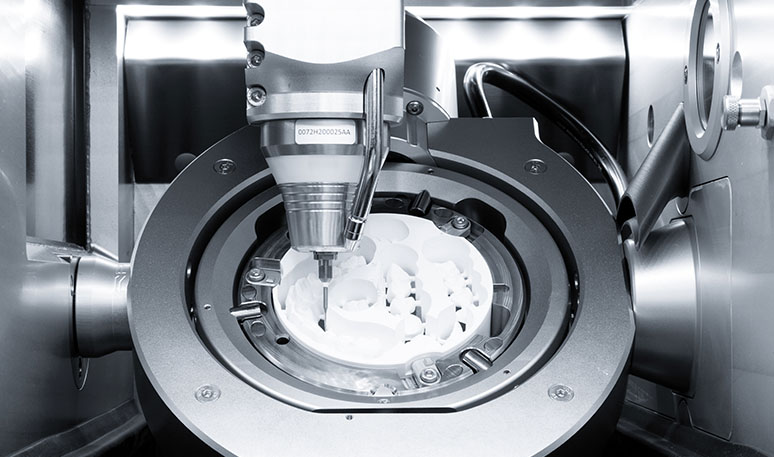

- Computer-controlled stand-alone milling unit with Teleskoper Orbit (⌀ 125 mm) for inserting blanks with ⌀ 95 mm, ⌀ 98 mm, ⌀ 106 mm and ⌀ 125 mm

- Integrated PC with touch screen for direct control (loading of tools, controlling of milling and calibration processes)

- Fully automated 5+1 axis simultaneous milling technology

- The following blanks can be inserted (for some, holders are required): Material blanks with ⌀ 95 mm, ⌀ 98 mm, ⌀ 106 mm and ⌀ 125 mm as well as 9 glass-ceramic and 6 Raw-Abutment® blanks

- The blanks can be removed from the orbit and allow a high-precision repositioning in μm range when re-inserted

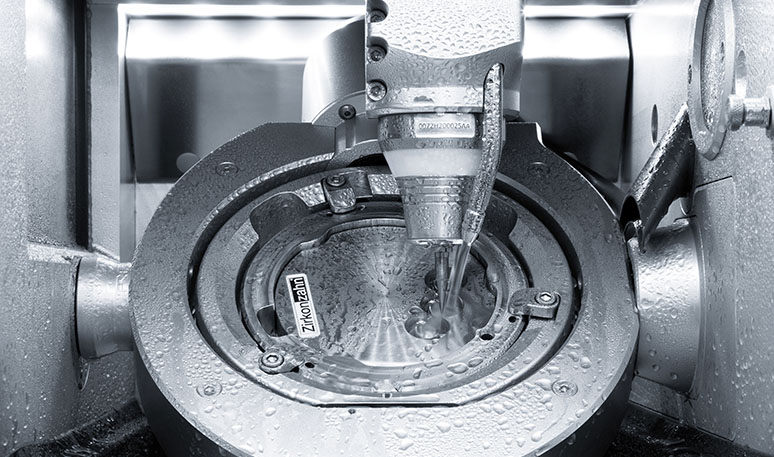

- High-performance milling spindle with optimised cooling water supply for particularly gentle material elaboration

- With wet processing function for processing all common dental materials and kinds of restorations (zirconia, resin, wax, Sintermetall, cobalt-chrome, titanium, Raw-Abutments®, glass-ceramics and composite)

- CAD/CAM milling bur 6 mm and orbit with opposed rotary axes (A and B) for a stable elaboration process; elaboration time can be varied by selecting different surface qualities

- Spaciously designed, optimally illuminated and easily accessible milling chamber

- Contamination-protected tool chamber, which is separated from the milling chamber, with automatic 21-compartment tool changer function

- Optical tool detection for a secure selection of the suitable milling tools

- Integrated space for the organised storage of up to three additional tool magazines, with 21 tool slots each, 84 tool slots in total

- Automatic self-cleaning and drying function and Cleaning Kit for manual cleaning

NEWM2 Teleskoper milling unit

Accessories

|

|

New! Tool magazine D6

with 21 tool slots for the storage and organisation of tools

Item number: ZBAC4201 |

|

|

New! Ioniser M2 / M2 Dual right

Device for the electrostatic discharge of plastic shavings for more cleanliness during the milling process

Item number: ZBAC3321 |

|

|

New! Blank Holder ⌀ 95 Teleskoper

Holder for fixing material blanks with a diameter of ⌀ 95 mm, in combination with Teleskoper Orbit

Item number: ZBAC2850 |

|

|

New! Blank Holder ⌀ 98 Teleskoper

Holder for fixing material blanks with a diameter of ⌀ 98 mm, in combination with Teleskoper Orbit

Item number: ZBAC2830 |

|

|

New! Blank Holder ⌀ 106 Teleskoper

Holder for fixing material blanks with a diameter of ⌀ 106 mm, in combination with Teleskoper Orbit

Item number: ZBAC2840 |

|

|

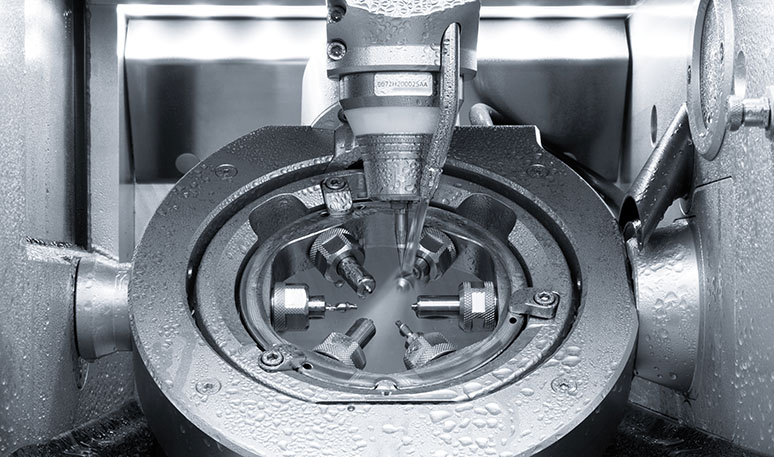

New! Raw-Abutment® Holder 6 Teleskoper

Holder for fixing and for the serial processing of up to six prefabricated titanium abutment blanks (Raw-Abutments®), in combination with Teleskoper Orbit

Item number: ZBAC2800 |

|

|

New! Glass Ceramics Holder 9 Teleskoper

Holder for fixing and for the serial processing of up to nine glass-ceramic blanks, in combination with Teleskoper Orbit

Item number: ZBAC2820 |

|

|

JawPositioner Support

Support used to fix the JawPositioner into the orbit of the Zirkonzahn milling unit

Item number: ZBAC3511 |

|

|

New! Blank Holder Teleskoper Soft

Resin holder for fixing soft material blanks (zirconia, resin, wax, wood and Sinternit).

|

Processable materials

| Zirconia |

Resin |

Wax |

Wood |

Sinter

metal |

Chrome-

Cobalt |

Titanium |

Raw-

Abutment® |

Glass

ceramics |

Composite |

|

Technical specifications

|

| Weight |

155 kg |

|

| Width |

77 cm + 15 cm Cleaning Kit |

|

| Height |

69 cm |

|

| Depth |

66 cm |

|

| Casing |

Hardened Securit glass UNI ISO 12150 |

|

| Processing axes |

5+1 |

|

| Power capacity |

600 W |

|

| Operating voltage |

100 – 240V |

|

| Power input |

2.6 A (5.5 A) |

|

| Chuck |

⌀ 6 mm |

|

| Spindle speed |

Depending on equipment |

|

| Torque |

13 Ncm |

|

| Orbit |

Teleskoper Orbit (⌀ 125 mm) |

|

Workpieces

(some with special holders

at extra charge): |

1x material blank ⌀ 95 mm, ⌀ 98 mm, ⌀ 106 mm as well as ⌀ 125 mm, up to 9 glass-ceramic blanks, up to 6 prefabricated titanium abutment blanks (Raw-Abutments®), JawPositioner transfer pattern |

|

Further information and accessories