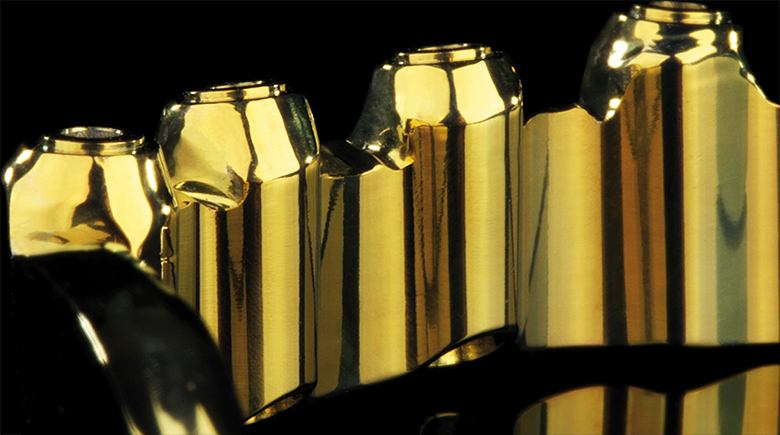

CAD/CAM Milling Metal

Metal course – The beginner course about metals

A Zirkonzahn expert introduces you to the world of metal milling with theoretical and practical examples

| Target group: | All those interested in Zirkonzahn CAD/CAM systems and new users | ||

| Course duration: | 1,5 days | ||

| Participants: | 6 | ||

| Venue: | Zirkonzahn Education Center Brunico other venues on request | ||

| Content: | First, we have some hard facts on the different metals and milling units for you. Afterwards, we model possible applications like abutments, crowns and bridges and prepare the milling units for the manufacturing. Furthermore, we show you in detail everything you need to consider when producing metal restorations and you receive useful tips for the organisation of the workflow. |

Program

Day 1 (all-day)

- Information about the hardware components of the Zirkonzahn CAD/CAM system (wet grinding, filter, cleaning, Raw-Abutment® Holder ...)

- Scan process and design of a reduced 3-unit bridge, discussion about the settings regarding different materials

- Milling a designed bridge

- Designing a single crown

- Milling one of the designed sinter metal single crowns

- Discussion about the CAD/CAM Bars software module

- Designing a bar

- Information about sinter metal by means of the milled single crown (elaboration, sintering furnace ...); starting the sintering process

- Answering open questions and milling the bar.

Day 2 (morning)

- Checking the milled bar and the sintered single crowns

- Designing a Raw-Abutment® and joint nesting

- Discussion about possible errors which can occur during the nesting

- Milling of the Raw-Abutment®

- Examination of the milling results

- Resolve outstanding issues