NEWM6 Teleskoper Blank Changer milling unit

INNOVATION AND PROGRESS – OUR DRIVING FORCES

|

In an increasingly fast moving world, where time is one of our most precious resources, it becomes more important than ever to keep an open mind and explore new paths. We are constantly looking for new solutions to do things better. With our innovations, we want to automate processes, speed up procedures and increase the dental workflow productivity so that our customers can focus on fundamental things – their craftsmanship. With our new M6 milling unit, we have met these requirements. | ||||||

OVERVIEW OF THE CHARACTERISTICS

|

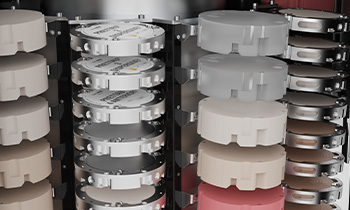

Large blank storage Despite its compactness, the blank storage of the M6 milling unit offers space for up to 16 or 80 blanks (upgradeable). Via the separate pull-out blank storage, blanks can be inserted manually or by means of the full-automatic Blank Changer. Furthermore, a camera recognises the material blanks via QR code so that the blanks can be intelligently sorted. Using a calibration block (included in the scope of delivery), the blank storage can perform a self-measurement and recalibrate itself in case of any deviations. |

|

|

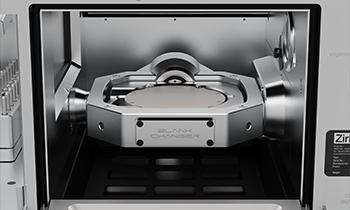

Full-automatic Blank Changer The 5+1-axis simultaneous milling unit is equipped with a Blank Changer which automatically transfers the material blanks from the storage to the orbit and places them back in the storage once the milling process is complete. This means that restorations can be now produced fully automatically without any manual intermediate steps, using several dental materials in different colours and heights. |

|

|

Full control The Blank Changer has an integrated ToF (Time of Flight) sensor, which monitors the blank presence as well as the slots in the storage. In addition, each slot is equipped with a LED status display. The different colours indicate to the user whether an action is necessary (e.g. loading and unloading of blanks, incorrectly loaded blanks, etc.). |

|

|

Teleskoper Orbit SelfLock We also remained true to the proven “Teleskoper” philosophy. With the Teleskoper Orbit SelfLock (Ø 125 mm) material blanks with a diameter of 95, 98, 106 and 125 mm can be now fixed and processed fully automatically. In particular, the Ø 125 mm blanks have been designed in such a way that they can be inserted and milled without any additional blank holder. |

|

|

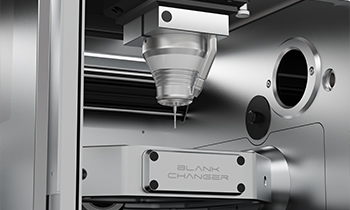

Performance Spindle Our M6 milling units are equipped by default with the new Performance Spindle. Thanks to a specially developed Permanent Magnet Synchronous Motor (PMSM) is optimally adapted to the milling unit, this spindle can reach a maximum torque of 200 Ncm at speeds of 6.000 to 50.000 rpm with a peak power of 2.5 kW. |

|

|

Up to 60 working slots The M6 milling unit is equipped with a contamination-protected tool chamber which is separate from the milling chamber and features an automatic tool changer function. With space for up to two storages with 30 slots each, up to 60 milling tools can be stored in a safely and orderly manner. Before and after milling tools are automatically checked for type or damage. |

|

|

Autonomous subtractive production Once the blank storage has been loaded and the milling files prepared and transferred to the machine, the M6 works autonomously thanks to the full-automatic Blank Changer. Thanks to the automatic self-cleaning and drying function, the Cleaning kit for manual cleaning and the Ioniser, which electrostatically discharges resin shavings, dirty milling chambers belong to the past. |

|

|

Easy access for maintenance The M6 has been equipped with a newly developed swing door which allows fast, uncomplicated and autonomous maintenance through frontal access. This means there is no need, for example, to remove covers or panels to carry out maintenance on ball screws or recirculating ball bearing, saving a lot of time. In addition, a regular maintenance of the machine parts increases their durability. |

Download

|

|

Insert M6 Blank Changer |

TECHNICAL DATA

| Weight | 220 kg (180 kg milling unit + 40 kg blank storage) |

|

|

|

| Width | 109 cm (+ 14 cm Cleaning Kit) |

|

|

|

| Height | 69 cm |

|

|

|

| Depth | 62 cm (plus connection for suction system) |

|

|

|

| Casing | with hardened Securit glass ISO 12150 |

|

|

|

| Electrical power | 2000 W |

|

|

|

| Operating voltage | 100 – 240 V~; 50 – 60 Hz |

|

|

|

| Milling unit processing axes | 5+1 |

|

|

|

| Blank Changer processing axes | 2+2 |

|

|

|

| Tool changer | Automatic, 60x |

|

|

|

| Number of tools | 60 (2 storages with 30 slots) |

|

|

|

| Milling spindle | Performance Spindle with Permanent Magnet Synchronous Motor (PMSM): 6.000 - 50,000 rpm |

|

|

|

| Milling spindle power | max. 2,5 kW |

|

|

|

| Milling spindle torque | 20 Ncm constant - 200 Ncm maximum |

|

|

|

| Blank storage | 16 or 80 blanks (upgradeable) |

|

|

|

| Blank management | Automated blank management with optical blank detection |

|

|

|

| Material blanks | Ø 95 mm, Ø 98 mm, Ø 106 mm, Ø 125 mm |

|

|

|

| Milling angle A/B axis | ± 30° |

|

|

|

| Bur/chuck diameter | Ø 6 mm |

|

|

|

| Bur length | Up to 60 mm |

|

|

|

| Measurement accuracy | ± 0,001 mm (1 μ) |

|

|

|

| Tool damage detection | Automatic |

|

|

|

| Compressed air | Input 6.5-9 bar, 120l/min at 6.5 bar, max. 400l/min (chamber cleaning) |

|

|

|

| Motors | Brushless with encoder (dual encoder in x axis) |

|

|

|

| Noise level | < 60 dB |

|

|

|

| Linear axis resolution | ± 0,001 mm (1 μ) |

|

|

|

| Rotation axis resolution | ± 0,00045° = ± 0,00000785 rad |

|

|

|

| Tool management | Automatic |

|

|

|

| Suction system (external) | Integrated power output up to 2000 W, built-in control relay for external devices |

|

|

|