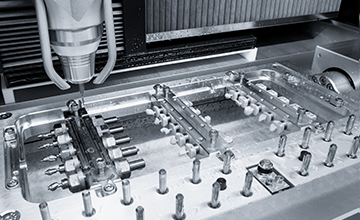

M4 Wet Heavy Metal Milling Unit – The all-rounder

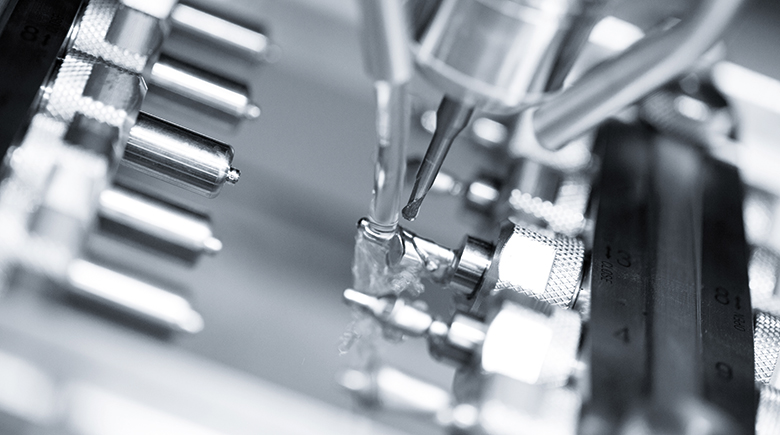

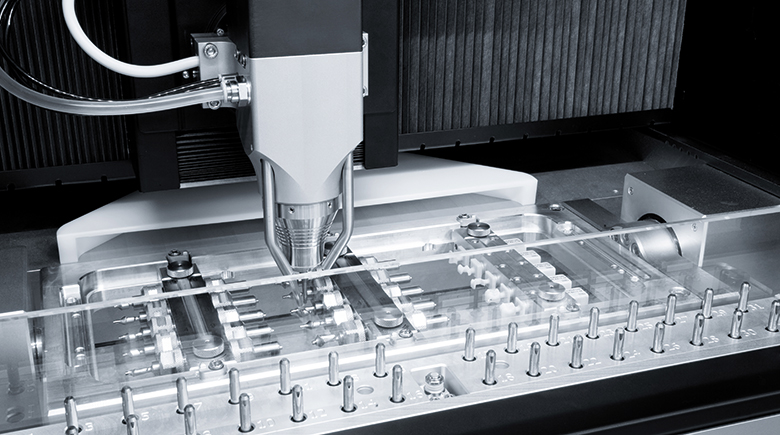

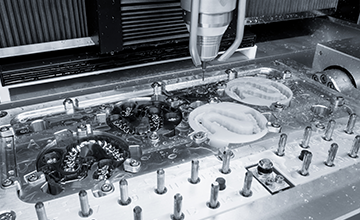

The M4 Wet Heavy Metal is a 1500 W and 350 kg milling unit, which withstands all vibrations. It is equipped with the proven 5+1 axes simultaneous milling technology and can process both hard and soft materials, thanks to the integrated wet processing function. The centrepiece consists of a 360° rotatable workpiece table, which makes it possible to mill also hard-to-reach areas, as undercuts and divergences without any problems. The extra-large milling area with different types of blank holders permits the elaboration of up to 10 models, 20 full-arch bridges and

30 Raw-Abutments® or glass-ceramic blanks in a single milling process. The integrated tool changer function and the tool magazine allow the automatic exchange of up to 32 elaboration tools. The optical tool detection (optional) prevents the use of wrong elaboration tools. As a stand-alone solution with integrated PC and touchscreen (optional), milling processes and calibration processes can also be started directly on the milling unit and elaboration tools can be loaded.

Basic Equipment

- Computer-controlled 5+1 axis simultaneous milling unit with 32-fold tool changer and wet processing function for processing of all dental prosthesis materials (zirconia, resin, wax, sinter metal, chrome-cobalt, titanium, precast titanium abutment blanks Raw-Abutments®, glass ceramics and composite)

- Different blank holder for round material blanks and other material forms:

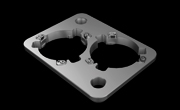

- 2-Blank-Plate M4

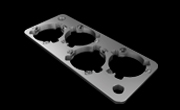

- 4-Blank-Plate M4

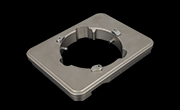

- Teleskoper Plate M4

- Raw-Abutment® Holder M4

- Glass Ceramics Holder M4

Overview of the characteristics

- 5+1 axes simultaneous milling technology optionally with Milling Spindle Hard Automatic or Performance Milling Spindle M4 (high performance, water-cooled milling spindle with integrated suction device; at extra charge)

- For processing zirconia, resin, wax, wood, Sintermetall, cobalt-chrome, titanium as well as precast titanium abutment blanks (Raw-Abutments®), glass ceramics and composite

- With an extra large milling area (39 x 17 cm) specifically suitable for the production of models

(up to 20 full-arch bridges) - NeW! Optical tool detection: the optical identification of elaboration tools ensures the selection of suitable tools and thus prevents milling errors caused by incorrect tool use

- The tool changer function and the tool magazine enable the automatic changing of up to 32 milling tools; the tools

are protected against contamination by a protective glass - The Ioniser (optional) ensures clean resin processing with a significantly shorter cleaning time

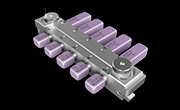

- Different combinable blank holders (partly included in the scope of delivery): 2-Blank-Plate M4, 4-Blank-Plate M4, Teleskoper Plate M4, Raw‑Abutment® Holder M4, Glass Ceramics Holder M4, Combi-Holder Raw/Glass M4, JawPositioner Support

- NeW! Stand-alone solution (optional): Integrated PC with touchscreen for process control directly on the milling unit

Accessories

Maximum flexibility

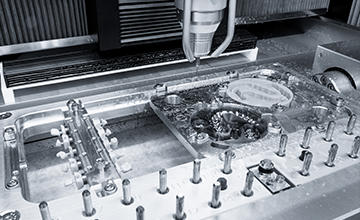

Depending on the work requirements, various blank holders can be combined in the 360° rotatable workpiece table:

|

|

|

| Option 1 Workpiece table with extra-large Model Blank M4 Beige – for the production of up to 20 full arches in a single milling process. |

Option 2 4 Blank-Plate – Blank holder with inserts for up to 4 material blanks Ø 95 mm; in this way the different materials needed for a restoration can be processed in just one milling process. |

|

|

|

|

|

Option 3 3 x Raw-Abutment® Holder M4 – up to 30 Raw-Abutments® can be processed in a single milling process.3 x Glass Ceramics Holder M4 for the processing of up to 30 glass ceramic blanks. |

Option 4 2-Blank-Plate with a Raw-Abutment® Holder M4 each or a Glass Ceramics Holder M4 – for the processing of 2 material blanks Ø 95 mm, 10 Raw-Abutment® blanks or10 glass ceramic blanks. |

Processable materials with full equipment

|

Technical specifications

|

|

|||||

| Weight | 350 kg | ||||

|

|

|||||

| Width | 123 cm | ||||

|

|

|||||

| Height | 69 cm | ||||

|

|

|||||

| Depth | 84 cm | ||||

|

|

|||||

| Casing | Hardened Securit glass UNI ISO 12150 | ||||

|

|

|||||

| Processing axes | 5+1 | ||||

|

|

|||||

| Power capacity | 1500 W | ||||

|

|

|||||

| Operating voltage | 100 – 240V | ||||

|

|

|||||

| Power input | 6.5 A (13.5 A) | ||||

|

|

|||||

| Chuck | Ø 6 mm | ||||

|

|

|||||

| Spindle speed | Depending on equipment | ||||

|

|

|||||

| Torque | 13 Ncm | ||||

|

|

|||||

| Workpiece | Model Blank M4 (39 x 17 mm), material blanks (Ø 95 mm), Raw-Abutments® | ||||

|

|

|||||